၂လက်မခန့်သော ကက်ပ်ဆူးလ်ဗန်ဒင်စက်များအတွက် ဝေးလံခေါင်သောနေရာမှ စောင့်ကြည့်ခြင်းနှင့် အချိန်နှင့်တပြေးညီ စာရင်းဇယားခြေရာခံခြင်း

IoT နှင့် မျှော်လင့်ချက်ပေါင်းစည်းမှုတို့သည် ၂လက်မခန့်သော ကက်ပ်ဆူးလ်ဗန်ဒင်စက်များကို အချိန်နှင့်တပြေးညီ စောင့်ကြည့်ခြင်းကို ဘယ်လိုအကောင်အထည်ဖော်ပေးသလဲဆိုတာကို လေ့လာပါ။

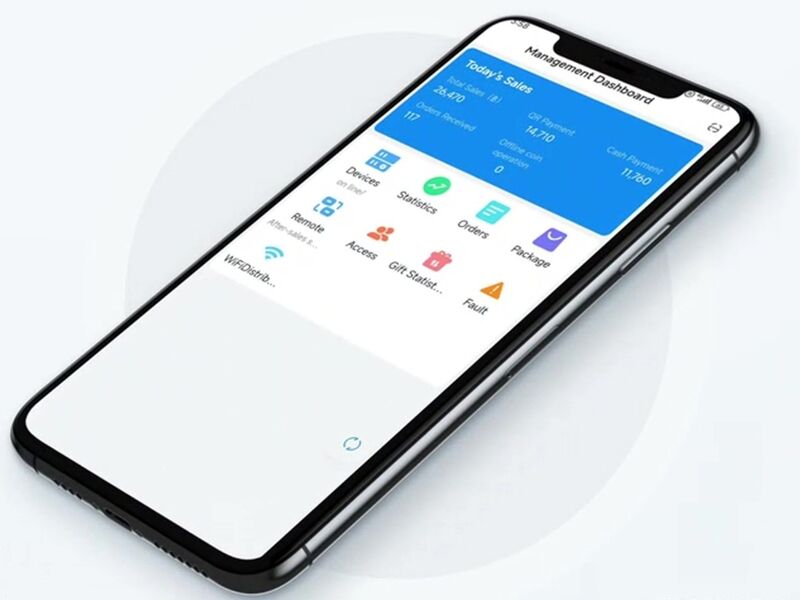

စက်ရုပ်ခေါ် ၂ လက်မအောက်က ကပ်စ်ယူးလ် စက်များတွင် IoT ဆင်ဆာများ တပ်ဆင်လိုက်သည့်အခါတွင် ၎င်းတို့ကို စိတ်ကြိုက်အားဖြင့် စီမံခန့်ခွဲမှု စင်တာများအဖြစ် ပြောင်းလဲပေးလိုက်ပါသည်။ ထိုကဲ့သို့ပြောင်းလဲပေးပြီးနောက်တွင် ထိုစက်များမှ စတော့ရှယ်ယူနစ်များ ကုန်လောက်ပြီဖြစ်ခြင်း၊ အတွင်းပိုင်းအပူချိန်များ၊ စက်တစ်ခုချင်းစီ၏ စွမ်းဆောင်ရည်များကို စီမံခန့်ခွဲမှု ပြင်ပြေးများသို့ တိုက်ရိုက်အသိပေးပို့ဆောင်ပေးပါသည်။ လွန်ခဲ့သောနှစ်က Ponemon ကုမ္ပဏီ၏ သုတေသနအရ ထိုကဲ့သို့သောစနစ်များကြောင့် စတော့ရှယ်စစ်ထောက်မှုများကို လုပ်သားအားဖြင့် ၄၀ ရာခိုင်နှုန်းခန့် လျော့နည်းစေပြီး စီမံခန့်ခွဲမှုများကို ၉၉.၈ ရာခိုင်နှုန်းအထိ အဆင်ပြေစေပါသည်။ ထို့အပြင် စတိုးစီမံခန့်ခွဲသူများအနေဖြင့် စက်များတွင် ပြဿနာများကို အမြန်စီမံနိုင်ခြင်း သို့မဟုတ် ထုတ်ကုန်များကို အသုံးပြုမှုတွင် အထူးအဆန်းဖြစ်ပေါ်လာမှုများကို စောစီးစွာ သတိပြုမိနိုင်ပါသည်။ အချို့သော အဓိကစနစ်များတွင် အမှတ်ပေးခြင်းအတွက် RFID စွမ်းရည်များကို ထည့်သွင်းလာပြီး ဖြစ်သောကြောင့် စက်များကွန်ရက်တွင် ပစ္စည်းတစ်ခုချင်းစီ၏ တည်နေရာကို တိကျစွာ စီမံခန့်ခွဲနိုင်မည့် အခွင့်အလမ်းကို ပေးစွမ်းပါသည်။

စိတ်ကြိုက်စတော့ရှယ်စီမံခန့်ခွဲမှု စနစ်များကြောင့် စတော့ရှယ်ကုန်လောက်မှုကို ၆၅ ရာခိုင်နှုန်းအထိ လျော့နည်းစေခြင်း

ယခုအချိန်မှာ ထုတ်ကုန်တွေ ရောင်းချမှုအမြန်နှုန်းကို ကြည့်ပြီး အရင်က ဘာတွေဖြစ်ခဲ့တယ်ဆိုတာနဲ့ နှိုင်းယှဉ်ပါက မိုးကုတ်စနစ်တွေက စတော့ရှယ်ယာပြဿနာတွေကို တစ်ရက်ကနေ ၁၂ ရက်အထိ ကြိုတင်ခန့်မှန်းနိုင်ပါတယ်။ ဤကုန်ပစ္စည်းများကို ခန့်မှန်းရန် ကိရိယာများကို အသုံးပြုသည့် အလုပ်သမားများက သူတို့ကိုယ်တိုင် လက်တွေ့စီမံခန့်ခွဲနေခဲ့သည့်အချိန်ကာလကို နှိုင်းယှဉ်ပါက စျေးဆိုင်ရှေ့တွင် ကုန်ပစ္စည်းများ မရှိတော့သည့် အခြေအနေကို နည်းပါးစေသည်ဟု ဆိုပါသည်။ ဤအချက်ကို အထောက်အပံ့ပြုသည့် ဂဏန်းတစ်ခုလည်း ရှိပါသည်။ နောက်ပိုင်းတွင် စီးပွားရေးလုပ်ငန်းတစ်ခုကို ကြည့်ပါက ဆိုင်များသည် လူများသည် အများဆုံးဝယ်ယူသည့်နေရာများတွင် ကုန်ပစ္စည်းများကို အတိအကျ စုဆောင်းပြီး သေးငယ်သည့်မြို့နယ်များတွင် ဝယ်ယူသူမရှိသည့် ကုန်ပစ္စည်းများကို များပြားစွာ မထားရှိတော့ပဲ နေ့စဉ်လူများစုနေသည့်နေရာများတွင် လူကြိုက်များသည့် ကုန်ပစ္စည်းများကို အများအပြားထားရှိနိုင်သည်။

မိုးကုတ်ချိတ်ဆက်ထားသည့် ကိရိယာများမှတစ်ဆင့် စတော့ရှယ် အချက်ပြမှုများ အလိုအလျောက်ပြုလုပ်ခြင်းနှင့် လက်တွေ့စွက်စားမှု လျော့နည်းခြင်း

ခေတ်မှီစနစ်များသည် စတော့ရှယ်ယာများ တွက်ချက်ထားသည့် နိမ့်ပါးသော အဆင့်အတန်းများအောက်သို့ ကျဆင်းသွားသည့်အခါတွင် ပြန်လည်ဖြည့်စွက်ရေးလုပ်ငန်းစဉ်များကို စတင်ပါသည်-

| အချက်ပြမှုအမျိုးအစား | လုပ်ဆောင်မှု ဖြစ်ပေါ်စေခြင်း | ပျမ်းမျှ တုံ့ပြန်မှုအချိန်လျော့နည်းမှု |

|---|---|---|

| စတော့ရှယ်နိမ့် (အရေးကြီး) | အဆင့်သတ်မှတ်ထားသည့် လမ်းကြောင်း အကောင်းဆုံးဖြစ်အောင်ပြုလုပ်ခြင်း | 73% |

| ရာသီအလိုက် တောင်းဆိုမှုများ တက်လာခြင်း | အလိုအလျောက် ပေးသွင်းသူများကို ဝယ်ယူရေးအမိန့်များ | ၆၅% |

| စက်ပျက်မှုများ | QR ကုဒ်ဖြင့်လမ်းညွှန်ထားသော ပြင်ဆင်ရေးစာရွက်စာတမ်း | 82% |

ယင်းသော ပရိုတိုကော်လ်များသည် အရေးပေါ်ဝန်ဆောင်မှုခေါ်ဆိုမှုများ၏ ၉၂ ရာခိုင်နှုန်းကို ဖယ်ရှားပေးပြီး အများဆုံးအသုံးပြုသည့် အချိန်များတွင် စက်မှုလုပ်ငန်းဆိုင်ရာ အဆင်သင့်ဖြစ်နေမှုကို ၉၈.၄ ရာခိုင်နှုန်းအာမခံပေးပြီး စက်အလိုက် ရှာဖွေစစ်ဆေးမှုများကို အသုံးပြုထားသော နည်းပညာရှင်များသည် အဆင်သင့်တွင် ရောက်လာကြသည်။

မျဥ်းကြောင်းအားဖြင့် ရောင်းအားအကျိုးဆောင်ခဲ့သည့် အကြံပြုချက်များနှင့် စားသုံးသူအချက်အလက်များ

စက်တစ်လုံးလျှင်ဝင်ငွေကို ၃၀% အထိတိုးတက်စေသည့် အချိန်နှင့်တပြေးညီ ရောင်းအားအချက်အလက်များ

ကလော်ဒ် အယ်လာနယ်လစ်တစ်နှင့်ပတ်သက်၍ ပြောရလျှင် အချက်အလက်များကို စွမ်းဆောင်ရည်ရှိသော အချက်အများအား ပြောင်းလဲပေးသည်။ အချို့သော လေ့လာမှုများအရ ဤကဲ့သို့သော ကိရိယာများကို သင့်လျော်စွာ အသုံးပြုပါက စက်များမှ ဝင်ငွေ ၂၈ မှ ၃၂ ရာခိုင်နှုန်းအထိ တိုးတက်မှုရရှိနိုင်သည်။ နည်းလမ်းမှာ ရောင်းအားကောင်းသော အချိန်များကို စောင့်ကြည့်ရှာဖွေခြင်းနှင့် ထုတ်ကုန်များကို ပိုမိုတင်းတင်းကျပ်ကျပ် ရောင်းချရန် ဆုံးဖြတ်ခြင်းတို့ဖြစ်သည်။ ဥပမာအားဖြင့် အမူဇမန်ပါခ် ကုမ္ပဏီတစ်ခုသည် မိသားစုဝင်များ စောင်းတို့ကို ဝယ်ယူရန် စျေးဝယ်သွားသောအခါတို့တွင် တစ်ဦးချင်းစီတွင် ၅၂၀၀ ဒေါ်လာခန့် တိုးတက်မှုရရှိသည်ဟု မှတ်တမ်းတင်ထားသည်။

ပိုမိုကောင်းမွန်သော ပြန်လည်စုဆောင်းမှုနှင့် နေရာချထားမှုဆုံးဖြတ်ချက်များအတွက် တောင်းဆိုမှုပုံစံကို မှတ်မိခြင်း

ကလော်ဒ်စနစ်များသည် လမ်းလျှောက်သူများ၏ လှုပ်ရှားမှုနှင့် ရာသီဥတုနှင့်ပတ်သက်သော စီးပွားရေးလှုပ်ရှားမှုများအပါအဝင် အခြားသော ၁၈ မျိုးကျော်ကို အသုံးပြု၍ ကော်ပိုင်းတို့အတွက် ဒေသတွင်းတောင်းဆိုမှုများကို ခန့်မှန်းပေးသည်။ ဤနည်းလမ်းမှာ စက်ရုံများအတွက်-

- AI မှတစ်ဆင့် ဝယ်ယူမှုများကို ခန့်မှန်းခြင်းဖြင့် ၂၂% အထိ လျော့နည်းစေပါသည်။

- စက်များကို မြင့်မားသော လမ်းလျှောက်သူအရေအတွက်နေရာများသို့ ပြောင်းရွှေ့ခြင်းဖြင့် ရောင်းအားသိသာစွာမြှင့်တင်ပါ။

2024 ခုနှစ် ဗင်ဒင်းစက်လုပ်ငန်းအလုပ်ရုံဆိုင်ရာလေ့လာမှုအရ ကလော်ဒ်အင်းလျော်တစ်ခုကိုအသုံးပြု၍ အကောင်းဆုံးဖြစ်အောင်ပြုလုပ်ထားသော နေရာများသည် လက်ဖြင့်စီမံထားသောနေရာများထက် ငွေပေးချေမှုပိုမိုရရှိခဲ့သည်။

AI စွမ်းအားဖြင့်ထောက်ပံ့ပေးသော အချက်အလက်များကိုအသုံးပြု၍ ကိုယ်ပိုင်အညွှန်းများနှင့် ဒိုင်နမစ်စျေးနှုန်းများ

ဗင်ဒင်းကိရိယာများမှ စားသုံးသူအပြုအမူများမှ စက်သင်ယူမှုကို အသုံးပြုသည့် တိုးတက်သောပလက်ဖောင်းများသည် ရုံးလုပ်သားများသည် ညနေ ၃ နာရီတွင်စိတ်ဖိစီးမှုကင်းစေသောကစားစရာများကို နှစ်သက်ပြီး စျေးဝယ်စင်တာတွင် အစားအစာစားပြီးနောက် စုဆောင်းသောအရာများကို နှစ်သက်ကြောင်းသိရှိပြီး စနစ်များမှ အလိုအလျောက်

- ပစ္စည်းအတွက် ထုတ်ကုန်အညွှန်းများကိုပြသပါသည်။

- တောင်းဆိုမှုများတက်လာသည့်အချိန်တွင် စျေးနှုန်းများကို ၁၅% အထိပြောင်းလဲပါသည်။

စောစီးစွာကျင့်သုံးသူများသည် စျေးနှုန်းများကို တစ်မျိုးတည်းထားသောစနစ်များနှင့် နှိုင်းယှဉ်ပါက စားသုံးသူများကို ၄၁% ပိုမိုထိန်းသိမ်းနိုင်သည်ဟုအစီရင်ခံကြသည်။

ချိတ်ဆက်ထားသော ဗင်ဒင်းကွန်ရက်များတွင် ကြိုတင်ပြုပြင်ထိန်းသိမ်းမှုနှင့် လည်ပတ်မှုယုံကြည်စိတ်ချရမှု

စက်ပစ္စည်းများ၏ အလုပ်လက်လျှော့ချမှုကို ၄၀% လျော့နည်းစေသည့် အချိန်နှင့်တပြေးညီ ဆေးကုသမှုစစ်ဆေးမှုများနှင့် ကြိုတင်သတိပေးချက်များ

စက်ပစ္စည်းများတွင် တပ်ဆင်ထားသော IoT ဆင်ဆာများသည် မော်တာအခြေအနေနှင့် ကုပ်ပရက်ဆာများ အလုပ်လုပ်ပုံတို့ကဲ့သို့ အရေးကြီးသော အစိတ်အပိုင်းများကို စောင့်ကြည့်ပြီး စက်ပျက်စီးမှုဖြစ်သောအခါတွင် ၁၂ နာရီမှ ၇၂ နာရီအထိ ပြဿနာများကို စောစီးစွာ ဖမ်းဆုပ်နိုင်သည့် အသိပညာရပ်များကို စမတ်စနစ်များသို့ ပို့ဆောင်ပေးသည်။ ၂၀၂၅ ခုနှစ်က ထုတ်ပြန်ခဲ့သော စက်မှုလုပ်ငန်းအစီရင်ခံစာများအရ ဤကဲ့သို့ ခန့်မှန်းနိုင်သော နည်းလမ်းများသည် ရုတ်တရက် ရပ်ဆိုင်းမှုများကို အမှန်တကယ် လျော့နည်းစေပြီး အဟောင်းများကို ပြုပြင်ထားသော နည်းလမ်းများနှင့် နှိုင်းယှဉ်ပါက ၄၀ ရာခိုင်နှုန်းခန့် လျော့နည်းစေသည်။ ဥပမာအားဖြင့် အပူချိန်ဆင်ဆာများကို ယူပါက အအေးပေးရောင်ရာများ၏ ဖိအားပြောင်းလဲမှုများကို ချက်ချင်းဖမ်းဆုပ်နိုင်ပြီး ဝန်ဆောင်မှုတောင်းဆိုမှုများကို အလိုအလျောက် ဖန်တီးပေးသည်။ ထို့ကြောင့် ပြဿနာများ ဖြစ်မသွားမီ နည်းပညာရှင်များကို ခေါ်ယူနိုင်ပြီး စက်များကို အလုပ်လုပ်စဉ်ကာလအတွင်း ထုတ်ကုန်များကို လုံခြုံစေသည်။ စက်ပစ္စည်းများ ၅၀၀ ခန့် ပါဝင်သော ကုမ္ပဏီများအတွက် ပြဿနာများကို စောစီးစွာ ဖမ်းဆုပ်နိုင်ခြင်းသည် ၂၀၂၃ ခုနှစ်တွင် ပိုနီမန်မှ ထုတ်ပြန်ခဲ့သော သုတေသနအရ တစ်နှစ်လျှင် ၇၄၀၀၀၀ ဒေါ်လာခန့် ခြွေတာပေးနိုင်သည်။

နည်းပညာရှင်များ၏ ပညာရပ်နှင့် အလိုအလျောက် ပြုပြင်ထိန်းသိမ်းမှု အကြောင်းကြားချက်များကို ညှိနှိုင်းပေးခြင်း

ယခုအချိန်တွင် ပုံမှန်ထိန်းသိမ်းပြုပြင်မှုများအတွက် AI စနစ်များမှ ခန့်မှန်းမှုများကို ၈၃% ခန့်အသုံးပြုနေကြပါသည်။ သို့ရာတွင် ပိုမိုရှုပ်ထွေးသော ပြဿနာများအတွက် လူသားများ၏ နည်းပညာဆိုင်ရာ အတွေ့အကြုံများ လိုအပ်နေဆဲဖြစ်သည်ကို ဘယ်သူမှ ငြင်းပယ်မှာမဟုတ်ပါ။ ၂၀၂၄ ခုနှစ်အစောပိုင်းက စုစည်းရရှိထားသော အချက်အလက်အချို့အရ နည်းပညာရှင်များက စက်များက ပထမဆုံး ပြဿနာဖြစ်နိုင်သည့်နေရာများကို သတိပေးပြီးနောက် အတွေ့အကြုံရှိသော ဝန်ထမ်းများက အလိုအလျောက်စနစ်မှ သတိပေးချက်များကို စစ်ဆေးပြီးမှသာ ပြုပြင်မှုများပြုလုပ်သည့် နည်းစနစ်ကို များသောအားဖြင့် ကြိုက်နှစ်သက်ကြကြောင်း တွေ့ရပါသည်။ ဤနည်းစနစ်များက ကျွန်ုပ်တို့အားလုံးကို စိတ်ညစ်စေတတ်သော ကွန်ဗဲလ်ဘဲလ်များ၏ အတားအဆီးများ သို့မဟုတ် ကျွန်ုပ်တို့၏ ၂ လက်မချောင်းသေတ္တာများတွင် ဒင်္ဂါးများ မကြာခဏ ကျအောင်ဖြစ်နေသည့် အကြောင်းရင်းကို ရှာဖွေရာတွင် အထူးထိရောက်မှုရှိပါသည်။ ကလောင်းစနစ်များကြောင့် အဖွဲ့များအလုပ်လုပ်ပုံပုံစံများလည်း ပြောင်းလဲသွားပါပြီ။ အွန်လိုင်း ဒက်ရှ်ဘုတ်များကြောင့် ဝေးလံသောနေရာများမှ အဖွဲ့ဝင်များက ကွန်ရက်အတွင်းရှိ စက်ပစ္စည်းများ၏ အခြေအနေကို တိကျစွာကြည့်ရှုစစ်ဆေးနိုင်သည့်အတွက် မျှော်လင့်မထားသော ပျက်စီးမှုများကို လျော့နည်းစေပြီး စနစ်၏ ယုံကြည်စိတ်ချရမှုကို တိုးတက်စေပါသည်။

၂ လက်မချောင်းသေတ္တာ ရောင်းချရေးစနစ်များအတွက် တိုးချဲ့နိုင်သော ကလောင်းအခြေပြု အခြေခံအဆောက်အအုံများ

စင်တာချုပ်များအတွက် ကလောင်းအခြေပြု တိုးချဲ့နိုင်သောစနစ်များ အသုံးပြု၍ ရောင်းစားစက်များစွာကို စီမံခန့်ခွဲခြင်း

ကလော့ဒ်နည်းပညာသည် အုပ်ရောင်းစက်များကွန်ရက်ကို စီမံခန့်ခွဲမှုပုံစံကို ပြောင်းလဲလိုက်ပြီး စတော့ရှယ်ယူနစ်မှ ထိန်းသိမ်းရေးလုပ်ငန်းများအထိ စီမံခန့်ခွဲမှုအတွက် အချက်အလက်များကို တစ်ပြေးညီစီမံနိုင်သည့် ဒက်ရှ်ဘုတ်များကို ပေးစွမ်းလျက်ရှိပါသည်။ ၂၀၂၄ ခုနှစ် ဗင်ဒင်းစက်များ လည်ပတ်မှုအစီရင်ခံစာအရ ကလော့ဒ်စနစ်ကို အသုံးပြုသည့် စီးပွားရေးလုပ်ငန်းများသည် အဟောင်းစနစ်ကို အသုံးပြုနေသည့် လုပ်ငန်းများထက် နေရာအသစ်များကို စတင်လည်ပတ်နိုင်မှုအချိန်သည် ၈၅% အထိ မြန်ဆန်ကြောင်းတွေ့ရပါသည်။ အဘယ်ကြောင့်အထူးတန်ဖိုးရှိသနည်း။ စက်ပေါင်းရာချီ သို့မဟုတ် ထောင်ချီစီမံနေသည့်အခါတွင် စျေးနှုန်းပြောင်းလဲမှုများ၊ ကန့်သတ်ကာလအတွင်း ပရိုမိုရှင်းများ သို့မဟုတ် ထုတ်ကုန်အမျိုးအစားများကို အသစ်ပြောင်းလဲမှုများကို တစ်ပြေးညီ အကောင်အထည်ဖော်နိုင်ခြင်းသည် အလွန်အရေးပါပါသည်။ ယူနစ်ပေါင်း ၅၀၀ ကျော်သို့ တိုးချဲ့လိုသည့်သူများအတွက် ဤကဲ့သို့သော စင်တာချုပ်ကိုင်စနစ်သည် အဆင်ပြေခြင်းထက် ယနေ့ဈေးကွက်တွင် ယှဥ်ပြိုင်နိုင်ရန် မရှိမဖြစ်လိုအပ်သည့် အခြေအနေသို့ ရောက်ရှိနေပါပြီ။

နေရာအများအပြားနှင့် ဖရန်ချိုင်းစီးဇင်များတွင် ပြောင်ပြောင်လက်လက် ချိတ်ဆက်နိုင်ခြင်း

ကလောင်းအာကိတက်ချိပ်ဆိုင်း ဒေတာ ဆီလိုးများကို စံထားသော API များမှတဆင့် ကော်ပိုရိတ်နှင့် ဖရန်စိုင်ဇီး စက်များအကြားမှ ဖယ်ရှားပေးပါသည်။ ဤသို့ပြုလုပ်ခြင်းဖြင့် နေရာတိုင်းကိုက်ညီမှု အမှားများကို ၇၂% လျော့နည်းစေပါသည် (၂၀၂၄ အလှူခံစာနယ်ဇင်းစာရင်း)။ ထို့ပြင် အသုံးပြုသူဝင်ရောက်ခွင့်ထိန်းချုပ်မှုများကိုလည်း ထောက်ပံ့ပေးပါသည်။ အကောင်းဆုံးဆိုင်များမှ အောင်မြင်သော ပုံစံများကို ၄၅ မိနစ်အတွင်း အခြားနေရာများသို့ ကူးယူအသုံးပြုနိုင်ပြီး စီမံခန့်ခွဲမှုကို ထိန်းသိမ်းထားနိုင်သည့်အလားအလာဖြင့် တိုးချဲ့မှုကို အမြန်တိုးတက်စေပါသည်။

မေးမြန်းမှုများ

အိုင်အိုတီ ဆင်ဆာများဆိုတာ ဘာလဲ။ စက်ရောင်းစျေးသည်များတွင် မည်သို့အလုပ်လုပ်ပါသလဲ။

အိုင်အိုတီ ဆင်ဆာများသည် အင်တာနက် ကွန်ရက်များကို အသုံးပြု၍ ဒေတာများကို စုဆောင်းပြီး လွှဲပြောင်းပေးသော ကိရိယာများဖြစ်ပါသည်။ စက်ရောင်းစျေးသည်များတွင် ပစ္စည်းကုန်လောက်မှုနှင့် စက်ပစ္စည်းအခြေအနေများကို စောင့်ကြည့်ပြီး အက်ဒ်မင်များအတွက် အချိန်နှင့်တပြေးညီ အချက်အလက်များကို ပို့ဆောင်ပေးပါသည်။

စက်ရောင်းစျေးသည်ကွန်ရက်များတွင် ကလောင်းပေါင်းစည်းခြင်း၏ အကျိုးကျေးဇူးများမှာ အဘယ်နည်း။

မိုးကုတ်ခြင်းအား စက်များကွန်ရက်ကို ဗဟိုပြု၍ စီမံခန့်ခွဲမှုကို ပေးသည်။ စတော့၊ စျေးနှုန်းနှင့် ထိန်းသိမ်းမှုအခြေအနေများကို ချက်ချင်းအသိပေးသည်။ နေရာအများအား စီမံသည့်အခါ လည်ပတ်မှုထိရောက်ထိသေ့မှုနှင့် တုံ့ပြန်မှုအချိန်ကို တိုးတက်စေသည်။

စက်ကွန်ရက်များတွင် ကြိုတင်ထိန်းသိမ်းမှုဆိုသည်မှာ အဘယ်နည်း။

IoT ဆင့်ကမ်းများကို အသုံးပြု၍ စက်ပျက်စီးမှုများကို ကြိုတင်ခန့်မှန်းပြီး အလုပ်လုပ်နေသည့်အချိန်ကို လျော့နည်းစေပြီး ကြိုတင်စွက်စဲမှုများဖြင့် ထိန်းသိမ်းမှုစရိတ်ကို လျော့နည်းစေသည်။

AI သည် စက်များ၏ လည်ပတ်မှုကို မည်သို့တိုးတက်စေနိုင်သနည်း။

AI သည် စားသုံးသူများ၏ အပြုအမူနှင့် ဝယ်လိုအားပုံစံများကို ခွဲခြမ်းစိတ်ဖြာပြီး စျေးနှုန်း၊ အကြံပြုချက်များနှင့် စတော့စီစဉ်မှုကို အကောင်းဆုံးဖြစ်အောင် ပြုလုပ်ပေးသည်။ အရောင်းနှင့် စားသုံးသူများကို ဆက်လက်ထိန်းသိမ်းမှုကို ထိရောက်စေသည်။

အကြောင်းအရာများ

-

၂လက်မခန့်သော ကက်ပ်ဆူးလ်ဗန်ဒင်စက်များအတွက် ဝေးလံခေါင်သောနေရာမှ စောင့်ကြည့်ခြင်းနှင့် အချိန်နှင့်တပြေးညီ စာရင်းဇယားခြေရာခံခြင်း

- IoT နှင့် မျှော်လင့်ချက်ပေါင်းစည်းမှုတို့သည် ၂လက်မခန့်သော ကက်ပ်ဆူးလ်ဗန်ဒင်စက်များကို အချိန်နှင့်တပြေးညီ စောင့်ကြည့်ခြင်းကို ဘယ်လိုအကောင်အထည်ဖော်ပေးသလဲဆိုတာကို လေ့လာပါ။

- စိတ်ကြိုက်စတော့ရှယ်စီမံခန့်ခွဲမှု စနစ်များကြောင့် စတော့ရှယ်ကုန်လောက်မှုကို ၆၅ ရာခိုင်နှုန်းအထိ လျော့နည်းစေခြင်း

- မိုးကုတ်ချိတ်ဆက်ထားသည့် ကိရိယာများမှတစ်ဆင့် စတော့ရှယ် အချက်ပြမှုများ အလိုအလျောက်ပြုလုပ်ခြင်းနှင့် လက်တွေ့စွက်စားမှု လျော့နည်းခြင်း

-

မျဥ်းကြောင်းအားဖြင့် ရောင်းအားအကျိုးဆောင်ခဲ့သည့် အကြံပြုချက်များနှင့် စားသုံးသူအချက်အလက်များ

- စက်တစ်လုံးလျှင်ဝင်ငွေကို ၃၀% အထိတိုးတက်စေသည့် အချိန်နှင့်တပြေးညီ ရောင်းအားအချက်အလက်များ

- ပိုမိုကောင်းမွန်သော ပြန်လည်စုဆောင်းမှုနှင့် နေရာချထားမှုဆုံးဖြတ်ချက်များအတွက် တောင်းဆိုမှုပုံစံကို မှတ်မိခြင်း

- AI စွမ်းအားဖြင့်ထောက်ပံ့ပေးသော အချက်အလက်များကိုအသုံးပြု၍ ကိုယ်ပိုင်အညွှန်းများနှင့် ဒိုင်နမစ်စျေးနှုန်းများ

- ချိတ်ဆက်ထားသော ဗင်ဒင်းကွန်ရက်များတွင် ကြိုတင်ပြုပြင်ထိန်းသိမ်းမှုနှင့် လည်ပတ်မှုယုံကြည်စိတ်ချရမှု

- ၂ လက်မချောင်းသေတ္တာ ရောင်းချရေးစနစ်များအတွက် တိုးချဲ့နိုင်သော ကလောင်းအခြေပြု အခြေခံအဆောက်အအုံများ

- မေးမြန်းမှုများ

EN

EN

AR

AR DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID VI

VI HU

HU TH

TH TR

TR MS

MS GA

GA LO

LO MY

MY